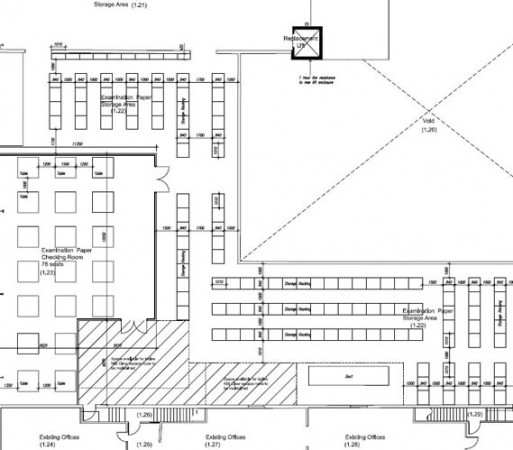

Warehouse Racking Layout

Designing the right layout for your pallet racking or shelving not only increases your storage capacity but can improve your productivity too.

Acorn Storage Equipment's senior salesmen explain how they go about planning pallet racking for warehousing and the required layout, and the key elements that need to be considered in warehouse design.

What do you take into consideration when planning a layout?

One of the first things we look at is the nature of the product being stored and how the operation works. If items arrive on pallets and are dispatched on pallets, the most common objective is to maximise storage. If stock is arriving in pallets or boxes, and being picked and packed to dispatch in smaller units, then we look at how people move around the warehouse, the work flow and the space needed for each element of the process.

How do you approach the initial design?

Our aim is always to keep it simple and not over complicate the design. We view the building as an empty box, in which pallet racking and shelving needs to be incorporated in a way that makes sense and creates a logical workflow.

If you over-complicate the warehousing layout, there’s a much higher chance things can go wrong.

That doesn’t mean that we can’t design layouts to cope with complex problems, but we always try to find the most logical and simplest solutions as these are the ones most likely to work in practice.

Are there different considerations when redesigning an existing warehouse racking layout?

We often deal with customers who want to get more storage in their current industrial unit. In which case we look at the existing layout and how it can be improved, either by changing the racking layout to narrower aisles and higher racking or by redesigning to create a better workflow. If goods are coming in on pallets and going out on pallets then a narrow aisle layout might be more suitable to increase storage capacity. We are increasingly working with companies who are switching to articulated forklift trucks like Bendi or Flexi to reduce the amount of aisle space required.

We regularly design a layout and project plan that can be completed in stages; stock can either be moved into outside storage or stacked temporarily in other areas as we rebuild the racking to increase capacity.

What do you need to take into account when moving a pallet racking system to new premises?

Moving to a new location presents another set of logistical issues. For a company with existing warehousing or distribution operations, minimising downtime is crucial. If the client is expanding and moving into a larger warehouse we can give the customer additional storage in their new warehouse so that goods can be moved to the new location in stages, particularly if we are incorporating their existing racking in the new racking layout design. Alternatively, Acorn is uniquely suited to provide a complete racking installation at their new premises and buy back or part exchange their existing racking.

Why is it important to use a reputable and professional company to design and install your racking and shelving?

We create racking layouts day in, day out so not only are we much quicker and more efficient, we have a wealth of expertise to draw on having seen what works in practice and what doesn’t.

At Acorn Storage all our racking layouts are designed to SEMA guidelines and installed by our SEIRS registered installers. We’re fully up to date with the latest industry recommendations and HSE regulations so that the racking project meets guidelines for clearance heights between shelves, weight loadings and best practice for staff moving around the warehouse. We also have £5million public liability insurance covering installation and products. And you’ll have a single point of contact throughout to ensure the racking project runs smoothly.

Most racking layouts will go through several changes during the project, particularly if there are changes being made to the building’s structure, so it’s our job as racking project managers to problem-solve so that the project meets the deadline, budget and desired end result.

Is the budget important?

Most companies use Acorn because we are able to supply quality new racking and we’re not tied to any one racking manufacturer or supplier. This means we can suggest the most cost-effective storage solution for our customers across a range of suppliers and from our own stocks of new racking, which are the largest in the South of England. This extends to our approach to designing the warehouse layout – providing our customer with logical, simple storage solutions that meet their objectives and budgets.

Our team at Acorn Storage are leading experts in warehouse layout design for pallet racking and shelving. We offer a full service including: design; supply of new and quality pallet racking and shelving; and professional installation.

Call us today on 01634 296927 to speak to our team of layout and racking experts or email [email protected]